Managing material costs is a priority concern for any construction project, especially when market conditions are volatile. At Crusader Fence, our expertise in material management, combined with smart design choices, innovative alternatives, and strong supplier relationships, allows us to keep projects on track—even as costs fluctuate.

Following are mitigation strategies that we employ to manage material cost volatility for our clients:

1. Informed Optimization

At Crusader Fence, our diverse expertise results in an informed approach to optimize materials and minimize costly change orders. We specialize in maximizing efficiency and minimizing waste during all phases of a project. Our team continually monitors material trends and adapts to ensure that the right materials are sourced and used in the most efficient way possible.

This means reducing waste and finding ways to optimize material usage. For example, we focus on minimizing offcuts and excess materials and using planned facility-fabricated elements when possible, which streamlines the construction process. Additionally, by staying informed about material trends, we can advise clients on cost-effective substitutions or adjustments to designs that won’t compromise the project’s quality or timeline.

Another critical advantage we offer is the ability to reduce costly change orders. By collaborating during the project planning stage, identifying strategic adjustments in advance, maintaining close communication throughout the project, and anticipating potential challenges, we can help clients define their needs early on and ensure that the project is designed and executed correctly from the start. This helps avoid delays and costly revisions later in the process.

2. Optimal Design Choices

One of the most effective ways to mitigate rising material costs is by assembling the project team early on to take advantage of smart design choices that optimize across all objectives, including function, aesthetics, and expense. At Crusader Fence, we prioritize collaboration between architects, engineers, and general contractors from the beginning. This allows us to make informed, cost-saving decisions that can significantly reduce material costs and improve project efficiency.

Early collaboration also prevents costly redesigns that often result from materials becoming unavailable or unexpectedly expensive later in the project. For example, during the design phase, our team can identify opportunities to use alternative materials that still meet quality expectations and project specifications. This approach not only saves money but also accelerates project timelines by reducing lead times and avoiding bottlenecks in material procurement.

3. Innovative Solutions

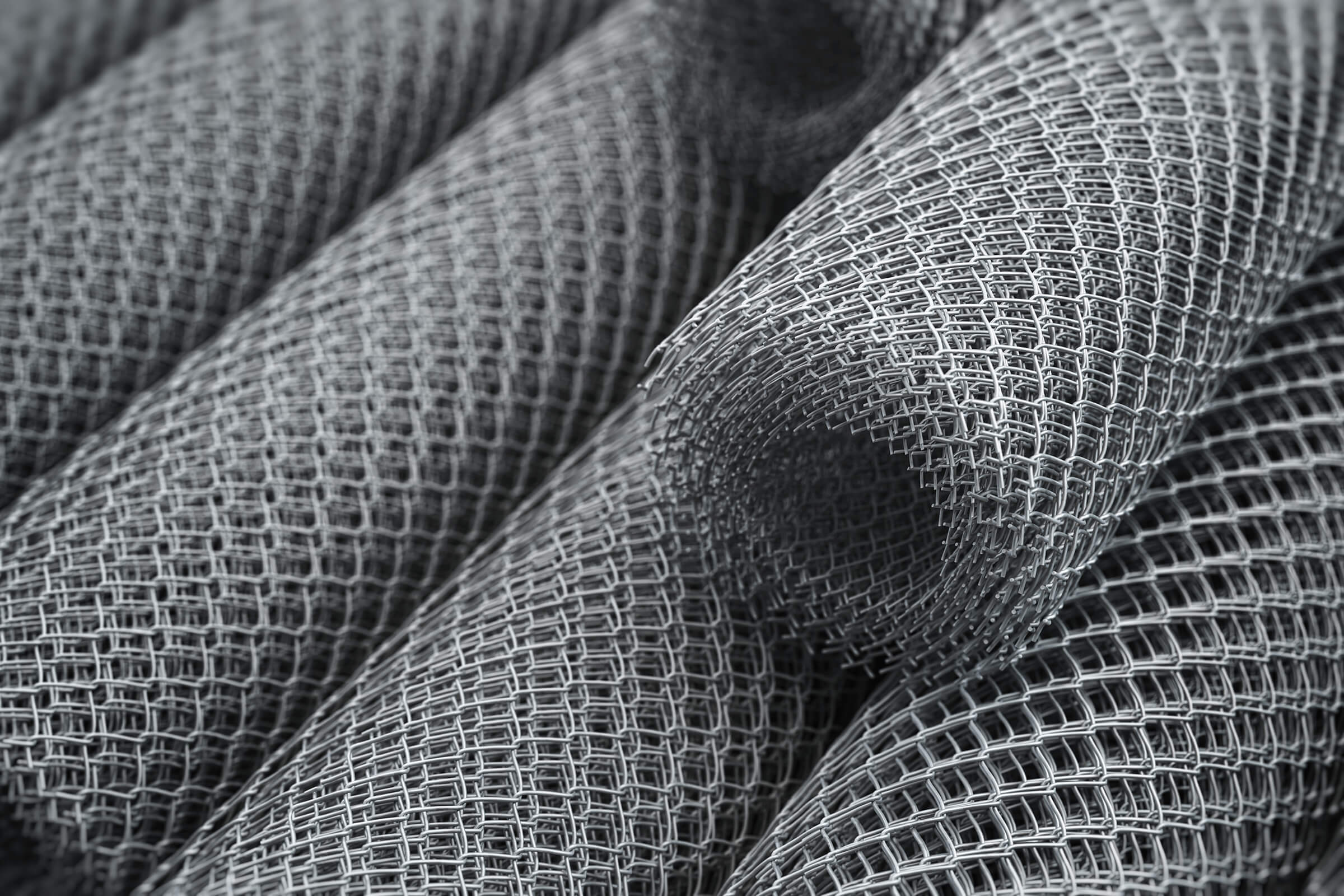

When material prices fluctuate, sourcing innovative and alternative materials is essential to controlling costs without compromising quality. Crusader Fence excels at exploring these alternatives, from using innovative materials to integrating advanced construction technologies that improve efficiency.

As the largest commercial fencing company in Northern California, our team is versed in a broad spectrum of materials that can perform as well or better than traditional options. Whether it’s exploring alternative wood species, using synthetic materials to abate conductivity concerns, or sourcing eco-friendly, sustainable components, we ensure that these alternatives meet the highest safety and durability standards.

We also adopt cutting-edge construction technologies, such as 3D modeling and prefabrication, to streamline construction processes, reduce waste, and save on labor costs. These technologies allow us to build smarter, not harder, keeping costs down while maintaining superior quality and craftsmanship.

4. Established Relationships

As an established contractor with a long history in the industry, Crusader Fence has built trusted, long-term relationships with our suppliers and has the financial viability to manage the rigors of complex commercial projects.

Our supplier relationships give us a distinct advantage when it comes to managing material costs. By partnering with suppliers who prioritize us, we gain access to competitive pricing, priority delivery schedules, and consistent material availability—even during periods of supply chain disruption. In a volatile market where material shortages and price spikes are common, having these reliable supplier relationships allows us to source materials more quickly and cost-effectively than many competitors.

Additionally, as a financially viable and reputable contractor, Crusader Fence is able to weather market fluctuations without compromising on project execution. Our financial strength ensures that we can procure materials in advance, lock in prices, and avoid delays that could otherwise impact project timelines and budgets. Clients can trust that our strong financial foundation and supplier connections will keep their projects moving smoothly, no matter how unstable the market.

Proven Solutions for Managing Material Costs

Managing fluctuating material costs requires an experienced, innovative, and financially stable contractor—qualities that Crusader Fence brings to every project. Through informed construction practices, early team assembly, innovative material exploration, and strong supplier relationships, we help our clients navigate the challenges of fluctuating prices and deliver projects on time and within budget. Partnering with Crusader Fence ensures that your project will benefit from expert planning, optimized material usage, and the best possible prices on high-quality materials.